Printing OMR (Optical Mark Recognition) sheets accurately is key to achieving reliable scanning results. Below are the recommended OMR printing guidelines for organizations, schools, testing agencies and survey administrators who use Addmen OMR Sheet Software.

Do not change the size of the OMR sheet design layout.

Avoid altering the proportions or margins—any change may affect bubble alignment and scanning accuracy.

Ensure the final print matches the exported design exactly.

Do NOT disturb the OMR circles or change the location of OMR bubbles while editing the design.

The bubbles must remain in the same positions as they were when exported by the OMR designer.

Even minimal movement can cause the scanner to mis-read or skip answers.

Do NOT alter the size of OMR bubbles.

The bubble size is designed to the software; changing it can result in mis-reads, multiple markings or blank readings.

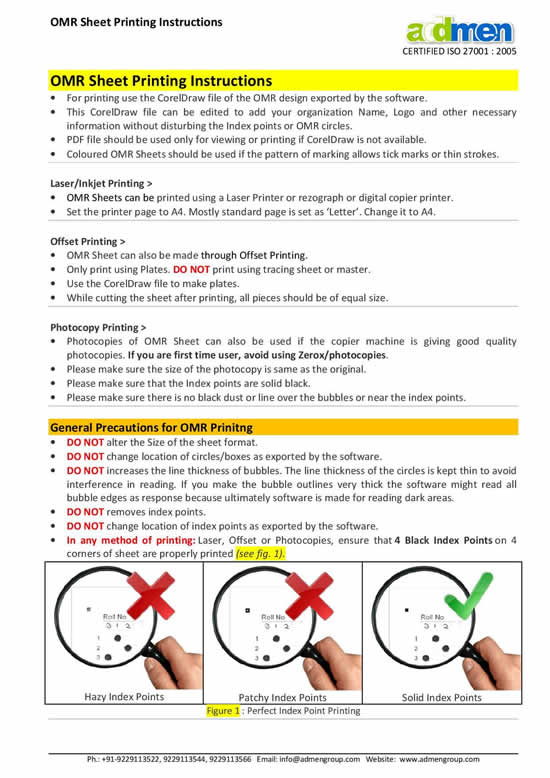

Maintain consistent print quality to preserve bubble shape and fill-area accuracy.

Use high-quality printing (laser or offset) to ensure crisp edges and proper contrast between filled and unfilled bubbles.

Avoid low-resolution printing or ink-jet printers with smudging risk — these may degrade scanning reliability.

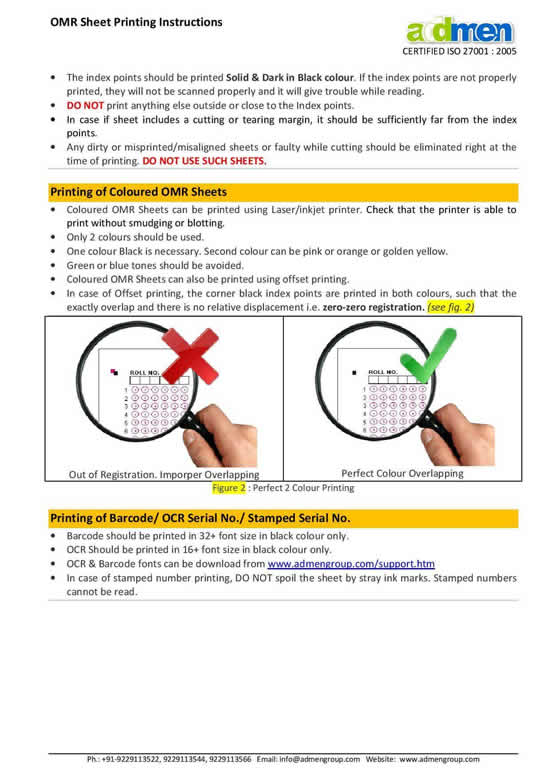

Ensure proper alignment during batch printing so each sheet is uniform.

If using coloured sheets (while optional) ensure colour contrast doesn’t interfere with scanner detection.

Always perform a test print and scan to validate before full production.

Adhering to these guidelines ensures that your OMR sheets will be properly processed by the scanner module of Addmen OMR Sheet Software. Deviating from the layout or bubble specifications may lead to:

By maintaining the original design format, correct bubble size and precise alignment, you guarantee consistent, error-free data capture and high throughput for examinations, surveys or exams.

Addmen Group Copyright 2025. All Rights Reserved.