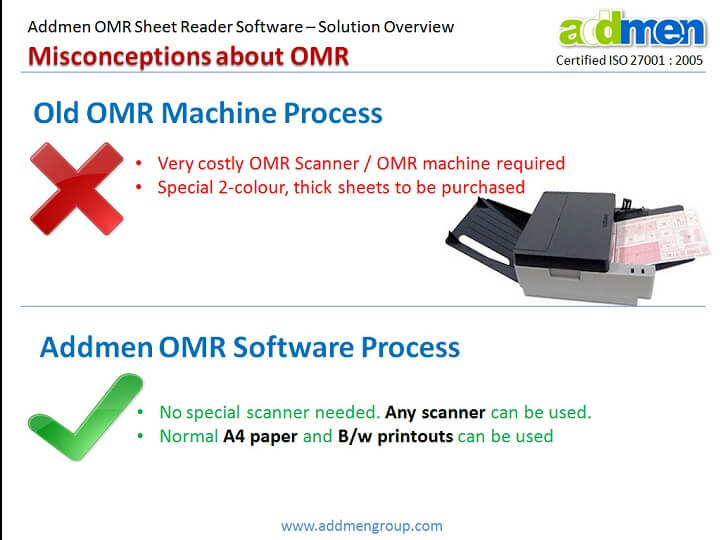

Many institutions still believe a special OMR scanning machine is required to process answer sheets or data-collection forms. While this was true in the past, modern OMR technology has shifted. Today, you can use a standard image scanner together with powerful OMR software to achieve excellent speed, accuracy and flexibility.

In this guide we compare the legacy OMR machine (hardware) with the modern OMR software-based solution. We’ll explain the pros & cons, cost considerations, operational workflow, and help you make an informed decision.

Optical Mark Recognition (OMR) refers to the automated capturing of marks (bubbles, check-boxes) on printed forms, such as MCQ answer sheets or survey response sheets.

In the context of assessments and data-collection, OMR enables:

Rapid processing of multiple-choice answer sheets and tick-box forms.

Better accuracy and fewer manual errors compared with manual entry.

Cost and time savings for large-volume processing.

Today’s discussion:

How it Works

A dedicated OMR scanning machine integrates both a high-speed sheet feeder/scanner and built-in data-reading capability. It uses special pre-printed OMR sheets and sometimes drop-out colours, registration marks etc.

Key Characteristics

Requires specialised hardware (often expensive).

Often uses specific sheet types (paper weight, print quality, special formats) for correct readings.

Deployment is more rigid; sheets must be physically present with the machine.

Pros & Cons

Very fast scanning throughput (when configured) for high-volume centers.

Integrated solution, less user configuration for sheet reading.

Cons:

High capital cost. As referenced by Addmen: “OMR Scanning machines cost around Rs. 200,000 for a well-configured model.”

Maintenance & wear-and-tear (mechanical parts, feeders) add hidden costs.

Less flexible: paper types, sheet design constraints, less easy to update on-the-fly.

Difficult to deploy across multiple locations without duplicate hardware.

How it Works

You scan OMR sheets using a standard flat-bed or ADF (automatic document feeder) scanner, then feed the scanned images into OMR software which performs recognition, reading and reporting.

Key Characteristics

Pros & Cons

Cons:

| Feature | OMR Machine (Hardware) | OMR Software + Standard Scanner |

| Capital / Cost | High upfront cost, maintenance required | Much lower upfront cost, minimal hardware |

| Flexibility & Deployment | Fixed location, special sheets required | Flexible, remote scanning possible, regular paper usable |

| Sheet Design & Printing | Specialized printers/format constraints | Design in-house, print on standard copier/lazer paper |

| Upgrades & Maintenance | Hardware wear & tear, slower upgrades | Software updates easier, hardware generic |

| Scalability | Must duplicate hardware for each site | Software license + scanners in each site works well |

| Ideal for | Massive centres with very high throughput | Schools, colleges, multi-site exams, data collection |

Organisations are realising that a hardware-only solution is becoming obsolete in the face of remote working, distributed exam centres and cost pressure.

For example: “OMR Machine = Expense: High CAPEX, ongoing maintenance, limited growth. OMR Software = Investment: Lower costs, flexibility, analytics and future readiness.”

Modern OMR software supports skew correction, image correction, works with regular A4 sheets and even photocopies.

Data-driven decision-making: software outputs allow analytics, dashboards, export to Excel/pdf.

Multi-location/remote scanning: branch offices scan and send data to central evaluation hub.

Initial cost: Hardware OMR scanners vs software licenses + standard scanner.

Running cost: Maintenance, spare parts for machine vs software updates, scanner cost.

Sheet printing cost: Hardware may require special paper/printing; software allows regular printing.

Time to deploy: Software route may be faster to roll out across multiple centres.

Scalability: If you plan to expand exam/data-collection to many locations, software route offers better return.

Future-proofing: Software solutions easily evolve with new requirements (bar-codes, QR codes, duplex scanning, cloud integration).

Assess your workload & scale: Number of sheets to process, number of locations, frequency of exams/surveys.

Evaluate infrastructure: Do you have branch centres? Do you need remote scanning?

Set budget: Compare total cost of ownership (hardware vs software) over 3–5 years.

Check sheet-design flexibility: Do you need customised forms? Do you want to print in-house?

Pilot test: Try scanning a batch using standard scanner + software to confirm accuracy, speed.

Plan deployment: Decide on centralised vs decentralised scanning, choose scanner model, train staff.

Review reporting & integration: Ensure OMR software supports data export, analytics, result generation.

Opt for support & upgrades: Choose a vendor who provides ongoing updates, remote support and maintenance.

If you are running a high-volume, single-centre operation with dedicated infrastructure, a hardware OMR machine may still work but will cost more and be less flexible.

If you are looking for cost-efficient, scalable, flexible scanning across multiple locations (or want more control over sheet design/printing), then OMR software plus a standard scanner is the smarter choice.

The shift in the industry is clearly towards software-based solutions. The legacy hardware-only model is being phased out.

Addmen Group Copyright 2025. All Rights Reserved.